SNCR system for medical incenerator plant

As part of this project, the Ecoexhaust team designed and installed an SNCR system on a newly built medical waste incineration plant.

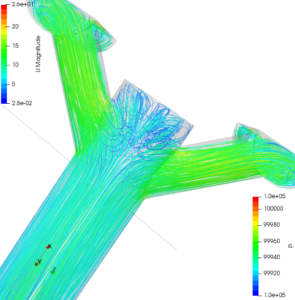

The main problem to be solved was to find the temperature windows and the appropriate mixing of urea with the flue gas. The SNCR system is cheaper and simpler than SCR, however, it requires more calculation before implementation. It is necessary to find the aforementioned temperature window, as well as the right place to swirl the flue gas so that the urea has a chance to mix homogeneously with the flue gas. Once the customer had provided the technical documentation, our team set about running numerical simulations to determine the temperature distribution at the various locations. It was determined that the best position for urea injection would be at the end of the afterburner chamber. There is also gas turbulence there, which helps in the uniform distribution of urea.

We installed two metering nozzles with air participation. The droplet size achieved was less than 60 µm D32. The droplet size achieved allows both rapid evaporation and reaching the center of the flue gas flow axis.

The supply of urea to the nozzles was implemented by diaphragm pumps controlled by the incinerator load signal and flue gas temperature.

Contact us

Our team is happy to answer any questions.

Contact

-

Bruzdowa 106a/13

02-991 Warsaw

woj. mazowieckie

Poland -

+48 506 508 330

+48 600 501 050 -

info@ecoexhaust.eu