Sea water injection

exhaust gas cooling

exhaust gas cooling

The Benefits of Sea Water Injection

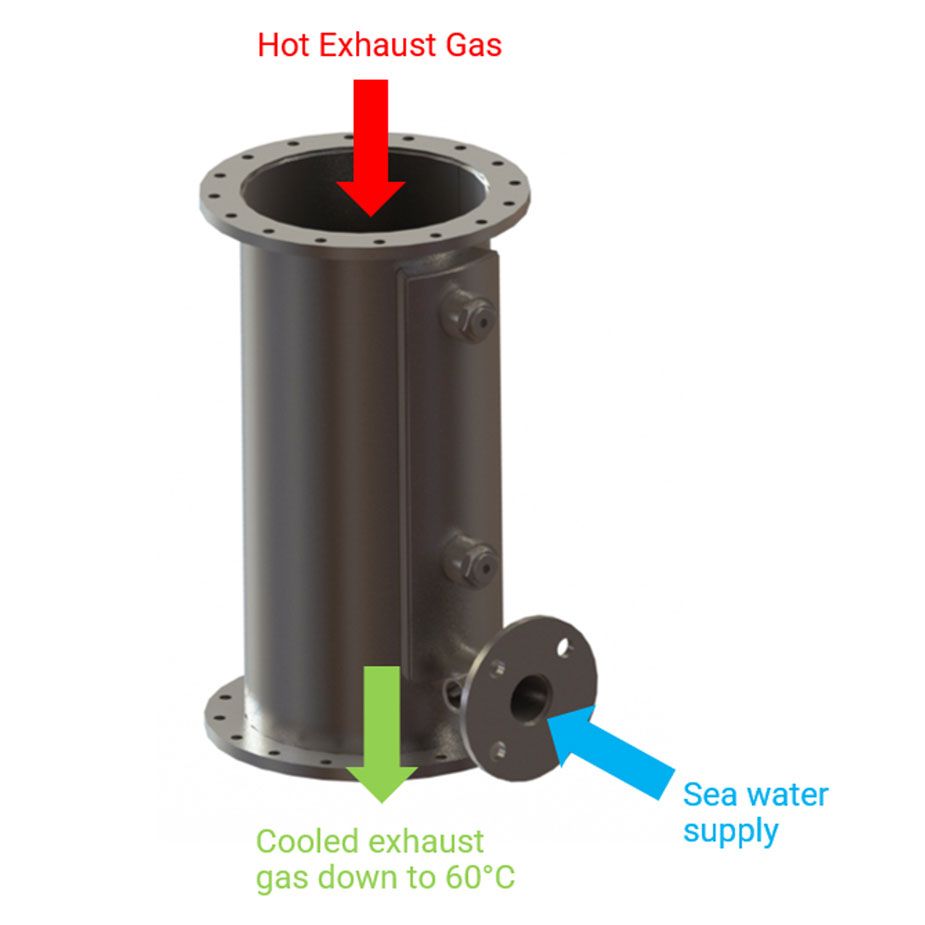

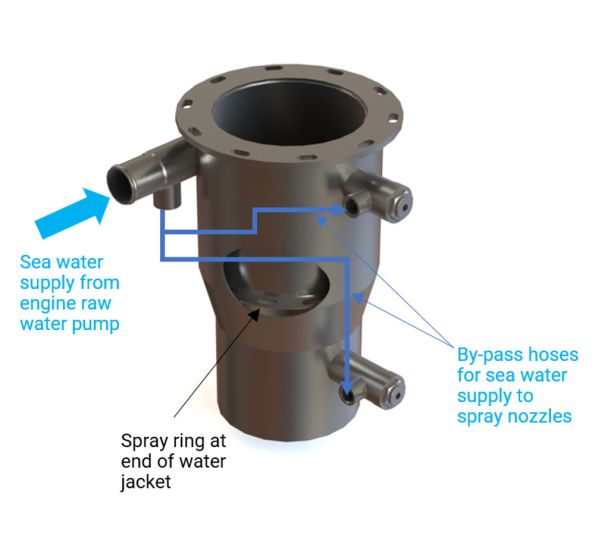

At wet exhaust gas systems, the sea water is used to cool the exhaust gas, for reducing emission of harmful components to the atmosphere and to increase safety onboard the vessels. Further, because of cooling the exhaust gas, the volume of the exhaust gas to be handled is considerably reduced, and hence the systems are more compact and lighter when compared to conventional exhaust gas systems. In the Navy/Defence application it also significantly enhances the stealth characteristics of the vessel for the infrared radars due to reduction of thermal emission of the unit. Thus, at our systems downstream from the SCR Reactor/Dry Silencer/Dry exhaust piping, in the sea water injector, the sea water is injected through dedicated several nozzles into the exhaust gas, and the exhaust gas is quenched to approximately 60°C.

Advanced Sea water injector

with flow regulation valve for secondary injection nozzle/s

Standard Sea water injector

Design of sea water injector

The injector sizing as well as amount and type of applied spray nozzles is performed based on engine’s data sheet with respect to given exhaust gas volume/mass flow as well as exhaust gas temperature. Base on those values the relevant size of the injector is considered as well as configuration of spray nozzles to secure proper mixing and then cooling of exhaust gas down to 60°C

Source of sea water supply and scope of supply

Depends on the project there can be different solutions applied for suppling the water to the sea water injector such us:

-

1. Discharged water from engine cooling line

-

2. By-pass from engine’s cooling raw water pump

-

3. Engine/Gearbox PTO mounted and driven flexible impeller sea water pump

-

4. Selected separate electrically driven sea water pump

The relevant solution is agreed and designed based on individual design of the vessel and its machinery. Seawater supply systems contains mostly the following items which are EcoExhaust scope of supply:

-

Seawater pump (with el. motor in case option 4 is selected from above)

-

Sea water Flexible hoses (with Class approval in case project requires)

-

Shut off valve

-

Check valve

-

Y-strainer

-

Regulating valves (mostly required for option 2 and 3 above)

-

Sea water pressure sensor with manometer connected to PLC

Contact us

Our team is happy to answer any questions.

Contact

-

Bruzdowa 106a/13

02-991 Warsaw

woj. mazowieckie

Poland -

+48 506 508 330

+48 600 501 050 -

info@ecoexhaust.eu